Free Shipping on Orders over $99 for Whole USA

What are the factores that affect the lifespan of MPO cable?

What Are the Factors that Affect the Lifespan of MPO Patch Cord?

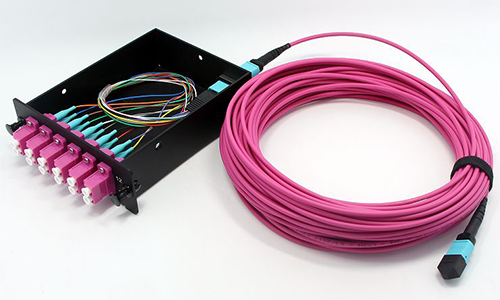

In the fast-evolving fiber optic world, ensuring your network's long-term efficiency is essential. MPO (Multi-fiber Push-On) patch cords play a key role in this. If you're in need of high-quality MPO patch cords, visit our online store for reliable options that will keep your network running smoothly. In this article, we'll explore the main factors that influence the lifespan of MPO patch cords.

Environmental Conditions

The environment in which an MPO patchcord is installed plays a major role in its lifespan. Factors such as temperature, humidity, and exposure to harsh conditions (such as dust, chemicals, and extreme weather) can accelerate wear. MPO cables are typically rated for specific temperature and humidity ranges. Operation outside of these ranges can result in insulation degradation, fiber damage, or even failure.

For example, high temperatures can cause the plastic components of a patch cord to soften and deteriorate over time. On the other hand, extreme cold can make the material brittle, causing cracking or breaking. To ensure the longevity of your MPO fiber jumpers, always adhere to the manufacturer's installation environment specifications and consider placing the cable in a protective enclosure.

Mechanical Stress and Handling

The physical handling of MPO patch cables is another key factor that affects their durability. MPO cables are designed to be flexible, but excessive bending, pulling, or twisting can damage the internal fibers or disrupt connector alignment. Repeated stress can cause micro-cracks or poor connections, which can reduce signal quality and shorten the life of the patch cord.

When installing or maintaining MPO patch cords, ensure that the bending radius is within the recommended limits. Use cable management tools such as cable ties, trays, or clips to avoid unnecessary strain on the cords. Additionally, avoid over-pulling cables, which can damage connectors and lead to fiber misalignment.

Connector Quality and Maintenance

The quality of the MPO connector itself is critical in determining the life of the patch cord. High-quality connectors ensure a stable, low-loss connection that is less susceptible to damage from environmental and mechanical factors. MPO connectors are very sensitive and prone to wear, so proper maintenance is required to extend their life.

Dirt, dust, and moisture can all cause contamination, which can lead to poor performance or connector failure. Regularly inspect connectors for signs of wear or contamination, and clean them with appropriate tools, such as fiber cleaning wipes or a blower, to avoid signal loss or degradation. Also, ensure that connectors are securely installed and are not accidentally pulled or twisted during operation.

Optical Performance and Signal Integrity

While MPO patch cables are designed for high-speed data transmission, signal integrity is an important indicator of their service life over time. Optical performance can degrade due to factors such as fiber bend loss, contamination, or connector misalignment. These issues may not result in immediate failure, but will cause a gradual reduction in signal strength, which can affect network performance.

To maintain optimal optical performance, signal strength must be monitored regularly using appropriate test equipment. If performance begins to degrade, inspect the cable for potential issues, such as damaged fibers or misaligned connectors. Proactively addressing these issues can prevent more serious problems and extend the overall life of the MPO patch cord.

Frequency of Use and Lifecycle Management

The frequency of use of MPO patch cords will also affect their service life. Cables that are frequently connected and disconnected will naturally wear out more than cables that are used for a long time. Every time a cable is connected to a connector, the connector and the optical fiber are subjected to a small amount of physical stress.

If your network needs to be frequently reconfigured or moved, make sure your MPO fiber jumpers have a high cycle rate. Practicing proper lifecycle management, such as replacing cables that show signs of wear, can also help ensure your system operates optimally without unexpected failures.

Conclusion

The lifespan of MPO patch cords depends on factors like environmental conditions, handling, connector quality, and signal performance. By choosing high-quality cables, following proper maintenance practices, and addressing issues early, you can ensure long-term reliability and reduce network downtime. To explore our range of high-quality MPO patch cords, click here and shop now at our online store.